How to Make a DIY Rocket Stove

Building a rocket stove is a rewarding project that lets you cook outdoors with little more than a few sticks for fuel. It's perfect for camping trips, backyard fun, or just a change of pace from the daily routine.

But hey, do we really need a specific reason to build something this awesome?

In this article, we'll guide you through the steps to create your very own rocket stove. Get ready to explore a new way of cooking!

What You'll Need

We’ll be making a rocket stove using the Chiasson Smoke rocket stove kit. You can use the full DIY rocket stove weld kit, or if you’re more adventurous, you can download just the rocket stove build plans.

If you want a few more options, we’ve compiled a list of the Best Rocket Stove DIY Weld Kits, so be sure to take a look! Anyway, moving on…

Here’s a full list of the materials:

Cook top bars and 4 tabs

Fuel chamber door, rod, and hinge

Intake tube, damper, damper rod, and coal grate

Ash pan, spring handle and rod, and back plate

Chimney and carry handle

Collapsible base, thumb screws, and weld nuts

The materials we’ll need are pictured here:

Make sure you have all components before getting started!

(If you’re short on tools or equipment, take a look at our recommended tools page.)

Step-by-Step Instructions

1. Intake Chamber: Coal Grate

Put a 1-inch spacer block underneath the coal grate, make sure things are level, then weld it together.

Check that the side width is at 4 inches. Sometimes the sides squeeze together, so if this happens, you can spread the sides apart by placing a bolt with washers inside and unfastening the washers.

2. Intake Chamber: Attach the air controller

Now let’s install the damper door. This will allow you to control the heat on your rocket stove.

First, put the damper rod into the pre-drilled holes. Then place the flap in and make sure it’s centered. Try to make sure the damper rod is facing downward as pictured, then go ahead and tack the damper door in place.

Double-check that everything’s operating correctly, then weld it together.

3. Fuel Chamber Door

Weld the door and hinge

Take the hinge and door, and weld the hinge onto the fuel chute. You’ll want to center the weldable hinge onto the fuel chamber, and make sure the hinge is hanging over the edge of the fuel chamber slightly so you can weld on the door.

Then go ahead and weld the door onto the hinge.

Weld on the door handle

Take the 2 ¾ rod, center it on the edge of the door, and tack it in place.

4. The Ash Pan

Weld the ash pan together

Weld the ash pan and the back plate together, centered as pictured. You can tack it right in the center, then weld both edges and the center afterward.

Weld the handle to the ash pan

Place the handle directly in the center of the ash pan wall and weld it on.

Weld the spring handle together

Take the spring handle and the 5⁄16 rod, and weld the rod in place against the edge of the spring.

Be careful, because the spring handle burns through pretty easily.

5. Weld the main parts together

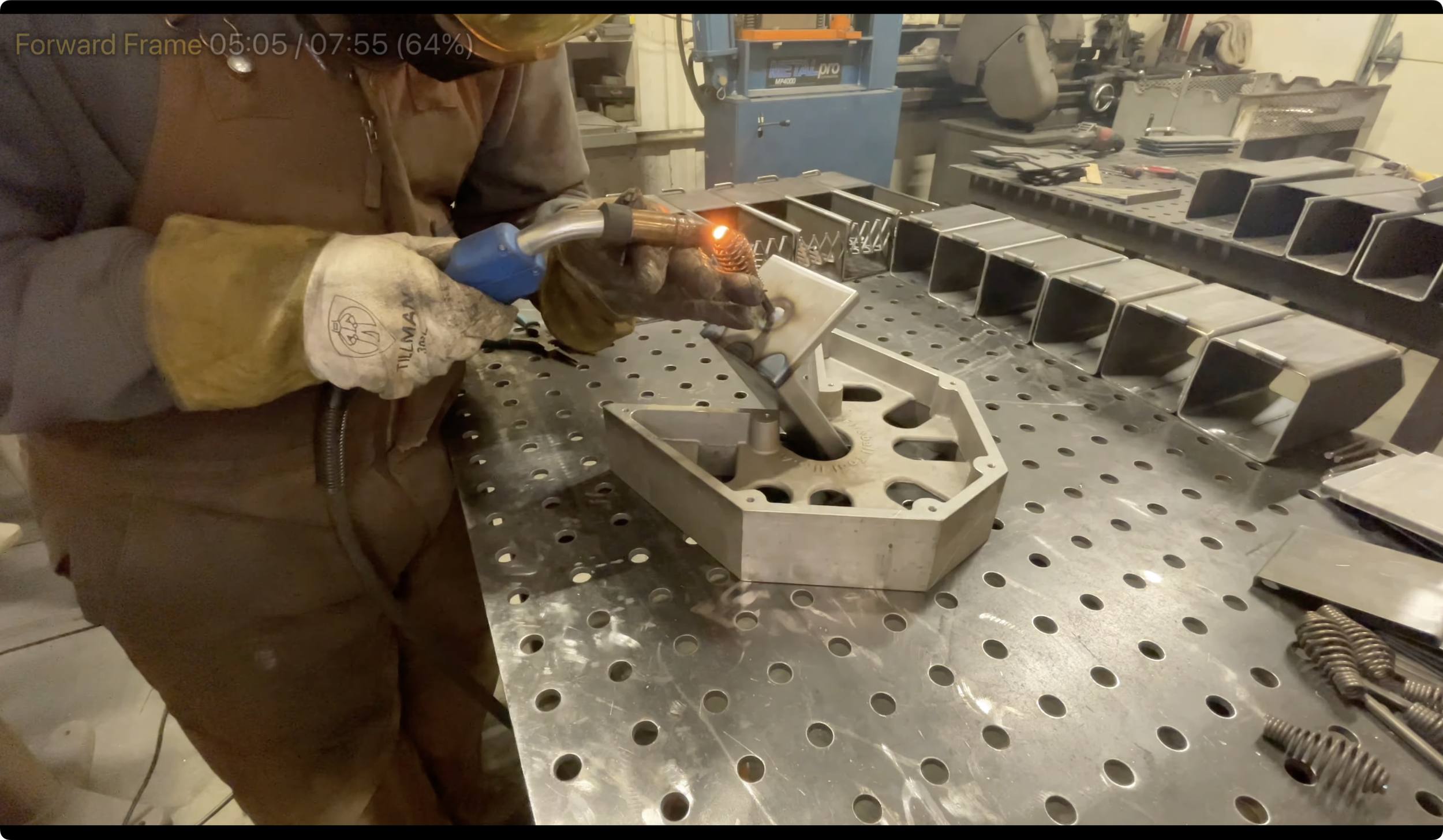

When you’ve gotten everything looking nice and clean, tack the intake chamber, fuel chamber, and chimney together as pictured. Start with the chimney (vertical) and intake chamber (horizontal), then move on to the fuel chamber (the smaller piece which comes out at an angle).

Make sure to position the fuel chamber so its door hinge is on the top!

Tip: Use a square to line everything up nicely, then you can use a bar clamp to tack the fuel chute onto the chimney and intake chamber.

Potential issues at this stage 🚨

If you’re finding that the pieces have an imperfect fit which is causing a gap, then just trim the edges.

If the ears on the fuel chamber spread out slightly, you can easily fix the spacing by hammering them back down.

Once everything is tacked together and attached snugly, go ahead and weld it together!

6. The Stove Top

Tubing mount

Grab 1 inch square tubing and the 4 tabs. Place each tab on each side, center the tabs about halfway, and weld the tabs to the square tubing.

Do not weld the tabs to the chimney! When you’re done welding, the tubing should be snug but still detachable.

Stove top

Take the stove top pieces, lay them together in a cross, and center them on top of the stove top. Tack them on, then weld them all around.

7. The Handle

Weld the handle to the side of the chimney. The placement is up to you, but keep in mind that if you put it a bit lower, you’ll be able to carry the stove on its side more easily due to the stove’s center of gravity.

8. The Collapsible Base

Grab the collapsible base parts and slide them together as pictured. Make sure the tip of the flame points more to the left if you’re looking directly at it.

Use a crescent wrench to make adjustments as necessary to ensure everything is aligned.

Bend the tabs

Use the crescent wrench to bend each of the four tabs inward.

When you’re done with that, you can place the rocket stove on top to make sure everything is fits correctly.

Weld on the weld nuts

Align the weld nuts with the holes in the tabs, and weld them on. Make sure the weld nut is on the outside, otherwise the rocket stove will no longer fit properly!

You can put a nut on the other side while you’re welding to hold everything in place.

Weld the seams

Don’t forget you’ll need to weld each of the seams of the tabs.

9. Clean Up

Use a wire brush to clean everything up.

Optionally paint it if you’d like, and season it any way you want. (Though if you’re thinking of painting it, you’ll definitely want to see our writeup on why we don’t paint our stoves anymore.)

You can also try your hand at building another stove with different materials.

And that’s it! You’re all done.

Conclusion

If you’ve made it this far, then congrats! Take that stove outside and grill some bacon– you’ve earned it. (If you need inspiration on what to cook, check out our article on perfect meals to cook on a rocket stove, or our Top 5 Easy Meals to cook on one.)

And hey, while you’re still here… If you have the itch to do another DIY welding project, then take a look at our DIY welding kits page.

Otherwise, you can browse our fully assembled rocket stoves, which are all hand-made in the USA, in the heart of Blue River, Wisconsin.